This article deals with the concept of PLC Programming, the types, and advantages of PLCs, its industrial applications, and usages along with some of the top PLC-based final year projects for engineering students.

Note:

Note:

Have you checked out our projects on PLC yet?

PLC Kit will be shipped to you and you can build using tutorials. You can start with a free demo today!

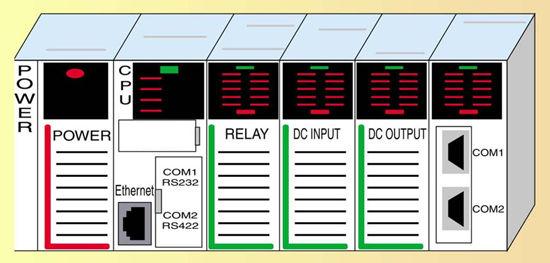

Programmable Logic Controller abbreviated as PLC is a digitalized and industry-based electronic computer system that is ruggedized to be employed in the industrial and manufacturing environment. PLCs are the major components in the automation industry, assembly lines, control systems and robotic devices. Basically, any activity pertaining to high-reliability control, processing fault diagnosis and ease of programming requires PLC to be installed in them.

A set of instructions either in the form of text or graphics, representing the logic to record and monitor run-time data such as machine productivity or operating temperature and other such specific industrial real-time applications, are consisted in PLC.

A software dedicated completely to PLC Programming comes from a PLC hardware of a certain specific manufacturer. The software permits the entry and development of user application code, which can then be downloaded to the PLC hardware. This software provides Human Machine Interface (HMI) i.e. an interface consisting of software and hardware that translates user inputs into signals for machines thus, providing the required result to the user.

PLCs replaces the old system of relay logic control wherein a set of relays is hardwired to carry out a specific task not only by performing switching tasks but also by executing the various operations like processing analog signals, counting, timing, sequencing, comparing, etc. If PLC is placed in run mode then it continuously keeps track of the various sensor outputs connected to its corresponding input modules, which then produces output decisions to the actuators according to the control function implemented in its program.

A PLC maintains an interface with other PLCs, computers or any other smart instruments via a communication network to perform functions such as downloading of programs, remote monitoring the devices, assists supervisory control and other such things.

Want to develop practical skills on PLC? Checkout our latest projects and start learning for free

Having robust construction and unique functional features inculcated within it, it is essentially built to withstand harsh environments such as extreme temperatures, vigorous vibrations, and electrical noises and high frequencies. Following points shows the usage of PLC in different fields:

Did you know

Did you know

Skyfi Labs helps students develop skills in a hands-on manner through PLC Online Courses where you learn by building real-world projects.

You can enrol with friends and receive kits at your doorstep.

You can learn from experts, build working projects, showcase skills to the world and

grab the best jobs.

Start Learning PLC today!

The following list shows the list of some top projects based on the emerging and innovative areas in the PLC sector. It can be built by engineering students to garner new skills and get hands-on experience in the sectors pertaining to PLC usages.

1. PLC Based Tank Filing System

In the automation industry, PLC is used to regulate the movements of heavy machines and develop effective car controls in order to increase productivity. In PLC, the program known as a ladder diagram is hosted in the control room. In order to receive commands from the control room, the field PLC is connected via an Ethernet cable. You can also integrate the internet of things to the PLC.

To carry out this PLC project you would require a PLC, a conveyer belt that connects to a DC motor, a Proximity sensor, and a pump. The ISPSOFT delta version is used to create the ladder diagram program while DELTA PLC is used to regulate the operation.

The PLC generates the command to pump water to the tank for a specific period of time (as mentioned in the Program). Once the tank gets filled, the conveyer begins to rotate for the next set of process operations.

2. Design and implementation of Automatic Door using PLC

This PLC project teaches you to design an Automatic Door using PLC Programming. As part of this project, you will develop an automatic door with the help of an infrared sensor. An IR sensor can measure the heat of an object as well as detects the motion. The programmable controller is endowed with strong ability, high reliability, flexible configuration, and easy programming. All of this is a measure of the means of contemporary industrial production and automation control equipment.

This PLC project creates an automatic door using PLC, IR Sensor, servo motor, limit switch and plywood. The door opens the moment a person walks towards the door and closes as soon as he passes through the door. The door remains closed when there is no physical presence of a human in its vicinity.

3. Interfacing of Proximity Sensor with PLC in Motor Speed Control application

A PLC consists of various types of I/Os that suitably match the industrial instrumentation and plant control interfaces. The ladder language offers flexibility in the programming options and is used for designing automatic control schemes and for regulating the working of machinery.

The goal of this project is to control the speed of the DC motor with the assistance of a Proximity Sensor, using PLC. Being simple, a DC motor has the potential to be implemented in a low-budget, application-specific, integrated circuit. The controller manipulates the characteristics of a majority of Electromechanical systems.

In this PLC project, you will use the proximity sensor to measure the real-time RPM of the motor. As per the reading, the voltage is regulated using PLC to achieve the required RPM of the DC motor. This controller can regulate the speed of the motor without the presence of any observer which leads to a significant reduction in the size and budget of the system.

Some other Final Year projects based on PLC Programming include:

Hope you got some good PLC based Final Year project topics from this article. If you have any good project topics, let us know in the comments.

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

Stay up-to-date and build projects on latest technologies